Pickhill Farm

Pickhill Farm,Tenterden, Kent.

By

Roger Putman

Martin Day’s father Stanley Day bought the 265 acre Pick Hill Farm near Tenterden in Kent in the 1930s.

It had but 30 acres of classic high wire hops. These were initially Fuggles but as Verticillium wilt took hold the slightly less susceptible Goldings variety was planted. The rest of the farm was given over to those typical crops of the Garden of England – apples, pears and cherries. Sheep would graze under the trees as there was room for them to do that in those days. Over the years the wire work and the structure of the oast houses needed attention so the hops were grubbed up in 1975 and in 1982, the Days sold the farm completely and started a nursing home business.

Happy holidays in the Isle of Man led to retirement here in 2007.

Martin fondly remembered the hop pickers descending on the farm from the docklands of East London. Often a few would come early armed with rolls of wallpaper to decorate the wooden walls of the huts. They would stuff farm straw into paillasses and collect farm firewood for the stove and the communal cooking facilities. In total, the 30 acres needed some 70-80 pickers in addition to 30 odd locals. Picking would take up to seven weeks.

Martin remembers there was never a problem getting the pickers; as someone dropped out there were plenty of volunteers wanting to make a bit of money and take a break from the pollution of the city. Even the sparrows coughed in Canning Town was an oft quoted remark. Children would come as well and would help picking when they were not messing about in the stream, climbing trees or blackberrying. As the hop season is early September, I suppose school attendance was not as rigorously enforced as it is now!

The bine was cut down and the family would pull the cones off into large baskets. Several times a day, the tallyman would come round to decant the collected hops into a calibrated bushel basket and mark up a notebook with the volume of hops picked. Too much leaf and the batch would not be accepted and would have to be cleaned up. Families hiding leaves at the bottom of baskets were soon found out! Pay day was Friday night when everyone repaired to the local pub.

As the sixties opened, pickers seemed to prefer the seaside at nearby Camber Sands if the weather was nice and if it was raining they would be quite happy playing cards indoors. They stopped coming in 1962 after the commissioning of a picking machine and the labour requirement dropped to just a dozen locals. The link with the East End community did continue with a Farm Adoption scheme where inner city children would get a chance of a day out in the countryside and the chance to spot a cow.

Martin told me that the stringing was a back breaking task without the use of traditional stiltmen and it would take some five weeks to get the wirework ready for training. The wires were 14-16 feet high. The string spent the night in the farm pond to stretch it so that it would tighten as it dried. Each plant had four strings, two had three shoots trained up them and the others just two. As the plants grew, organophosphorus insecticides were sprayed against inevitable aphids every ten days or so and Martin still carries the scars of carrying out this task in days when ‘elf and safety was less considered.

Another less than pleasant task was sulphuring the kilns. The oasts were direct oil fired for some eight hours and a heavy chain was placed on the flame. This was then manhandled into a tray of brimstone and wiggled about to vaporise the sulphur and give the hops a bright appearance so beloved of brewers who would inspect their cut block samples after the harvest.

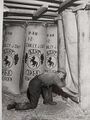

The hops were then pressed into pockets. Each had to weigh 168lbs so test pressings would take place to mark the appropriate level upstairs but usually a pressing until the oasthouse floor creaked alarmingly was adequate! The hops were dispatched to Paddock Wood via hop factors Wild, Neame and Gaskin and on to the Hops Marketing Board which oversaw quotas and payment. A cheque would appear in time for Christmas and another in June but you usually had to remind them to send it said Martin.