Macardle, Moore & Co, New Maltings at Dundalk: Difference between revisions

(Created page with "<big>'''NEW MALTING AT DUNDALK, IRELAND - MESSRS. MACARDLE, MOORE & CO. LTD</big>''' The accompanying .illustrations are, of a new 6o-quarter malting recently erected by Mes...") |

No edit summary |

||

| Line 1: | Line 1: | ||

[[File:Macardle Moore Ltd New MAltings Dundalk (4).jpg|thumb|250px]] | |||

[[File:Macardle Moore Ltd New MAltings Dundalk (8).jpg|thumb|250px]] | |||

<big>'''NEW MALTING AT DUNDALK, IRELAND - MESSRS. MACARDLE, MOORE & CO. LTD</big>''' | <big>'''NEW MALTING AT DUNDALK, IRELAND - MESSRS. MACARDLE, MOORE & CO. LTD</big>''' | ||

| Line 6: | Line 8: | ||

The walls are built of Belfast pressed brick, and in accordance with mode developments the roof is made flat, covered with vulcanite, upon which deposited a layer of shingle, affording protection to the top floor against changes of outside temperature. The vulcanite work was done by Vulcanite Co. Ltd, Belfast. The malting floors, which have an area of 12,250 square feet, are constructed of steel and concrete, the surface being cement, which is very finely trowelled up ; they are supported throughout steel girders and cast-iron columns. However, the walls, columns, girders, & are of somewhat lighter construction than usual, as the barley store is situ at on the ground floor instead of being near the roof in the usual way This barn has a capacity of 3,000 quarters, and has two elevators of a capacity 50 quarters per hour each, so that there is a minimum of labour in respect handling the grain. | The walls are built of Belfast pressed brick, and in accordance with mode developments the roof is made flat, covered with vulcanite, upon which deposited a layer of shingle, affording protection to the top floor against changes of outside temperature. The vulcanite work was done by Vulcanite Co. Ltd, Belfast. The malting floors, which have an area of 12,250 square feet, are constructed of steel and concrete, the surface being cement, which is very finely trowelled up ; they are supported throughout steel girders and cast-iron columns. However, the walls, columns, girders, & are of somewhat lighter construction than usual, as the barley store is situ at on the ground floor instead of being near the roof in the usual way This barn has a capacity of 3,000 quarters, and has two elevators of a capacity 50 quarters per hour each, so that there is a minimum of labour in respect handling the grain. | ||

[[category:Maltings]] | |||

Revision as of 14:33, 6 August 2019

NEW MALTING AT DUNDALK, IRELAND - MESSRS. MACARDLE, MOORE & CO. LTD

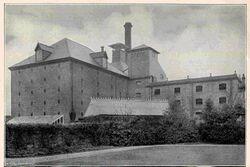

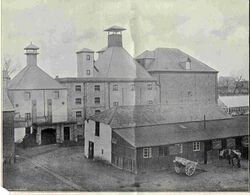

The accompanying .illustrations are, of a new 6o-quarter malting recently erected by Messrs. MACARDLE, MOORE, & CO. LTD., at their brewery in Dundalk, from the designs and under the superintendence of Messrs. BATCHELOR & HICKS, architects of Dublin and London.

The new malting is erected on the site of an old structure which it was found necessary to dismantle in 1905. As may be seen in the full page illustration, the end of the new building is dovetailed between a new kiln, on the left, used for retorrefaction purposes, and a quadrangular granary on the right, which Can hold 4,000 quarters of either barley or malt. The group of buildings (brewery and maltings) present an imposing view on arriving at the main entrance of the brewery, but so far as the new buildings were concerned, the exigencies of space compelled the architects to make effect a secondary consideration.

The walls are built of Belfast pressed brick, and in accordance with mode developments the roof is made flat, covered with vulcanite, upon which deposited a layer of shingle, affording protection to the top floor against changes of outside temperature. The vulcanite work was done by Vulcanite Co. Ltd, Belfast. The malting floors, which have an area of 12,250 square feet, are constructed of steel and concrete, the surface being cement, which is very finely trowelled up ; they are supported throughout steel girders and cast-iron columns. However, the walls, columns, girders, & are of somewhat lighter construction than usual, as the barley store is situ at on the ground floor instead of being near the roof in the usual way This barn has a capacity of 3,000 quarters, and has two elevators of a capacity 50 quarters per hour each, so that there is a minimum of labour in respect handling the grain.