<slideshow sequence="forward" transition="fade" refresh="3000">

The James's Street entrance to the 85 acre Guinness site in Dublin. St Patrick's windmill once served the Roe Distillery and at 150 feet high is one of the tallest in Europe.

These little sculptures were designed and installed by James P Moran who was the mechanical engineer involved in the 1989 copper project. He even put his own initials on them!

The Guinness Storehouse - note the Rotunda panoramic bar on top of the old fermenting room which once housed the world's largest FV at 12,000hL or 26 brl per inch of dip.

The modern exterior of the brewhouse

One of the problems of a city centre site - expensive apartments next to an industrial operation

There are three Buhler six roller mills working at 12t per hour on malt and 8t per hour on raw barley which is 30% of the grist

23.5t is mashed into each of four brewing streams every six hours. There are Steels mashers into three mash conversion vessels with a stepped infusion from 63

oC before transfer into these kieves for lautering. There are three 12m Balfour tuns and a pair of 10.2m diameter vessels in tandem

Another view of the lauter tuns or kieves

The run off grant, the wort is pale as the colouring material is added to the copper

Wort is run to four 1100hL underbacks which Guinness call upperbacks prior to the copper. These are by Huppmann dating from 1989

1989 vintage Huppmann copper/whirlpools

A view of the famous Harp insignia through the hop grist chutes to the coppers

Inside the brewhouse control room which was about to move into the fermenting block over the road

Hop pellet bags are slit and crushed to remove any lumps before addition

Once the control room moves to fermenting all these additions will be automated

Kettle finings tanks - powdered carageenan is slurried with water and roused with air before adding to the copper

Brewery pipe runs are complicated

The external calandria for the coppers

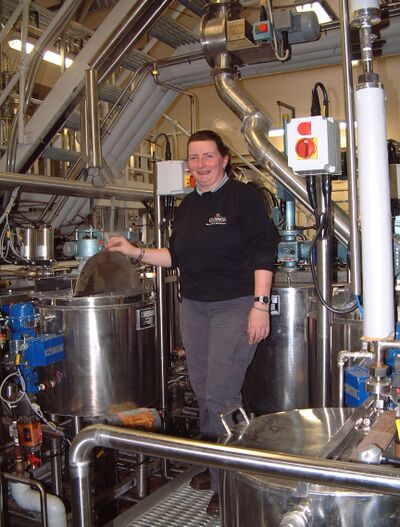

Brewer Breda Tanner in the Pilot Brewery

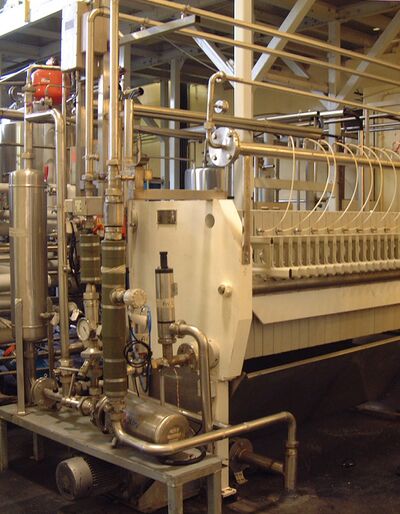

Mash filter in the Pilot Brewery

Brew vessels in the Pilot Brewery

Fermenting vessels in the Pilot Brewery

Any idea what this coil is for?

Hot liquor tank and brew plant in the Pilot Brewery

Yeast storage in the Pilot Brewery

A Pilot Brewery centrifuge on wheels

Sample kegs in the Pilot Brewery

Complex pipework in the Pilot Brewery

Bottling machine in the Pilot Brewery

The entrance to the old Vat House No1

Another view of the venerable porter vats

Another redundant building - they do help baffle the sound of brewery operations from well heeled neighbours

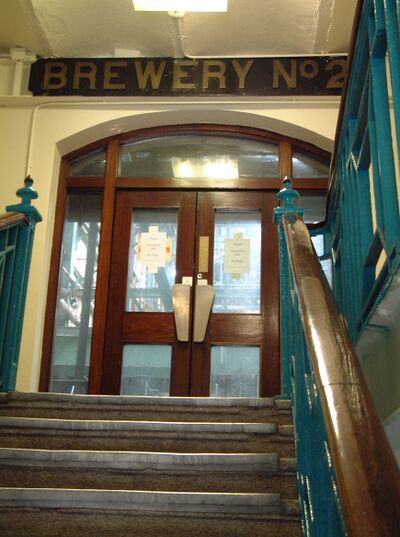

The steps into the redundant Brewery No2

The old mash conversion vessels in Brewery No2.

The central services building and some of the 21 fermenting vessels totalling 39,000hL

A bank of beer centrifuges

Close up of a Westfalia beer centrifuge

There are 32 maturation vessels totalling 114,000hL

More maturation vessels showing the complex pipework to fill and empty

General view of the kegging line. Roundings were odd kegs which did not fill a full pallet.

There are two Till rotary lines each filling 1000 kegs per hour

...which can handle 30 kegs at a time

Thirty 30L kegs destined for rail distribution

There is no smallpacking on the Dublin site. The drive through tanker bay handles 50 road tankers daily

Perry Atkins CO

2 liquefaction plant for gas recovered from active fermentations.

A drum roaster for making the coloured extract

Odd sections of the 600mm gauge railway remain

The old railway used a spiral tunnel under James's Street to change level between the riverside part of the site and the brewhouse

The pedestrian tunnel under James's Street is still in use

Seamus McGardle, head of Beverage Blending Agents with his map of worldwide Guinness operations and Project Brewer Gerry McGovern is on the right

</slideshow>

The James's Street entrance to the 85 acre Guinness site in Dublin. St Patrick's windmill once served the Roe Distillery and at 150 feet high is one of the tallest in Europe.

These little sculptures were designed and installed by James P Moran who was the mechanical engineer involved in the 1989 copper project. He even put his own initials on them!

The Guinness Storehouse - note the Rotunda panoramic bar on top of the old fermenting room which once housed the world's largest FV at 12,000hL or 26 brl per inch of dip.

The modern exterior of the brewhouse

One of the problems of a city centre site - expensive apartments next to an industrial operation

There are three Buhler six roller mills working at 12t per hour on malt and 8t per hour on raw barley which is 30% of the grist

23.5t is mashed into each of four brewing streams every six hours. There are Steels mashers into three mash conversion vessels with a stepped infusion from 63oC before transfer into these kieves for lautering. There are three 12m Balfour tuns and a pair of 10.2m diameter vessels in tandem

Another view of the lauter tuns or kieves

The run off grant, the wort is pale as the colouring material is added to the copper

Wort is run to four 1100hL underbacks which Guinness call upperbacks prior to the copper. These are by Huppmann dating from 1989

1989 vintage Huppmann copper/whirlpools

A view of the famous Harp insignia through the hop grist chutes to the coppers

Inside the brewhouse control room which was about to move into the fermenting block over the road

Hop pellet bags are slit and crushed to remove any lumps before addition

Once the control room moves to fermenting all these additions will be automated

Kettle finings tanks - powdered carageenan is slurried with water and roused with air before adding to the copper

Brewery pipe runs are complicated

The external calandria for the coppers

Brewer Breda Tanner in the Pilot Brewery

Mash filter in the Pilot Brewery

Brew vessels in the Pilot Brewery

Fermenting vessels in the Pilot Brewery

Any idea what this coil is for?

Hot liquor tank and brew plant in the Pilot Brewery

Yeast storage in the Pilot Brewery

A Pilot Brewery centrifuge on wheels

Sample kegs in the Pilot Brewery

Complex pipework in the Pilot Brewery

Bottling machine in the Pilot Brewery

The entrance to the old Vat House No1

Another view of the venerable porter vats

Another redundant building - they do help baffle the sound of brewery operations from well heeled neighbours

The steps into the redundant Brewery No2

The old mash conversion vessels in Brewery No2.

The central services building and some of the 21 fermenting vessels totalling 39,000hL

A bank of beer centrifuges

Close up of a Westfalia beer centrifuge

There are 32 maturation vessels totalling 114,000hL

More maturation vessels showing the complex pipework to fill and empty

General view of the kegging line. Roundings were odd kegs which did not fill a full pallet.

There are two Till rotary lines each filling 1000 kegs per hour

...which can handle 30 kegs at a time

Thirty 30L kegs destined for rail distribution

There is no smallpacking on the Dublin site. The drive through tanker bay handles 50 road tankers daily

Perry Atkins CO2 liquefaction plant for gas recovered from active fermentations.

A drum roaster for making the coloured extract

Odd sections of the 600mm gauge railway remain

The old railway used a spiral tunnel under James's Street to change level between the riverside part of the site and the brewhouse

The pedestrian tunnel under James's Street is still in use

Seamus McGardle, head of Beverage Blending Agents with his map of worldwide Guinness operations and Project Brewer Gerry McGovern is on the right