<slideshow sequence="forward" transition="fade" refresh="3000">

The brewery was opened in 1974

The brewery was designed to incorporate the shape of a viking longboat - the prow is the brewhouse

Corporate offices on site

Another view of road tankers

The bare concrete does present a rather austere facade

Steam issues from the viking longboat!

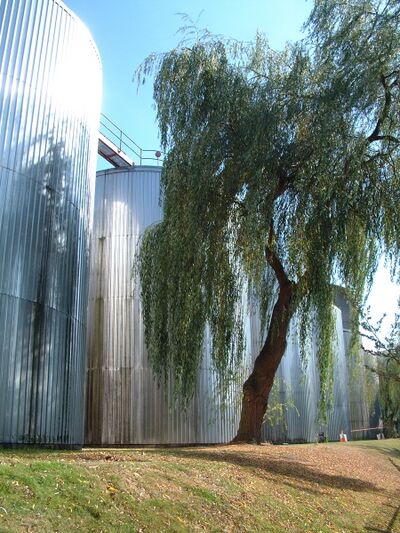

Two malt silos. One has nine 100 tonne cells and other six 200t

The chisel bottom of the silo cells in created by a huge conical bottom to the structure

The outfeed conveyors from the malt silos

CO

2 collection plant by Union Engineering from Denmark

60% of the beer bitterness comes from liquid extract. It is kept warm in a Decker cabinet.

The extract is tipped from a drum into the working tank

This device slits hop pellet boxes - it was awaiting its cabinet

Hop pellets are fed into the hop pots. Wort picks them up and pumps the hops to the coppers

Inside the cavernous brewhouse

The malt screens are by Buhler

The Chronos Richardson malt weighers

The hammer mill within its acoustic and explosion proof box

This 12 tonne Meura mash filter was installed in 1998

The wort balance tank on the Meura mash filter

The newer mash filter installed in 2002

Below the mash filter showing the spent grains discharge trough

The discharge to the spent grains tanks

High above the brew vessels

The two mash filters are at right angles to each other

Bare concrete walls in the brewhouse

The copper calandria by Huppmann

The vessel in the foreground is the whirlpool with the wort prerun vessel behind

The mash vessel will process 12 tonnes every two hours giving twelve 650hL brews a day. There are two mash lines

One of 74 x 1500hL conical bottomed fermenters

Equipment on the top of a fermenter

A view from the riverbank of some of the 34 x 7000hL conditioning tanks. The working corridor is underground.

Some of the 14 x 1250hL horizontal bright beer tanks

440mL cans of Skol coming off two can lines

The Krones can filler and Ferrum seamer

A record week on No1 can line

Bottle conveyors with the Sander Hansen pasteuriser on the right

The 1998 Krones bottling line works at 54,000bph

Change parts for the bottling line

The 16 lane APV kegging line dates from 1993 and will fill 1000 50L kegs an hour

Locator board handling is still manual

</slideshow>

The brewery was opened in 1974

The brewery was designed to incorporate the shape of a viking longboat - the prow is the brewhouse

Corporate offices on site

Another view of road tankers

The bare concrete does present a rather austere facade

Steam issues from the viking longboat!

Two malt silos. One has nine 100 tonne cells and other six 200t

The chisel bottom of the silo cells in created by a huge conical bottom to the structure

The outfeed conveyors from the malt silos

CO2 collection plant by Union Engineering from Denmark

60% of the beer bitterness comes from liquid extract. It is kept warm in a Decker cabinet.

The extract is tipped from a drum into the working tank

This device slits hop pellet boxes - it was awaiting its cabinet

Hop pellets are fed into the hop pots. Wort picks them up and pumps the hops to the coppers

Inside the cavernous brewhouse

The malt screens are by Buhler

The Chronos Richardson malt weighers

The hammer mill within its acoustic and explosion proof box

This 12 tonne Meura mash filter was installed in 1998

The wort balance tank on the Meura mash filter

The newer mash filter installed in 2002

Below the mash filter showing the spent grains discharge trough

The discharge to the spent grains tanks

High above the brew vessels

The two mash filters are at right angles to each other

Bare concrete walls in the brewhouse

The copper calandria by Huppmann

The vessel in the foreground is the whirlpool with the wort prerun vessel behind

The mash vessel will process 12 tonnes every two hours giving twelve 650hL brews a day. There are two mash lines

One of 74 x 1500hL conical bottomed fermenters

Equipment on the top of a fermenter

A view from the riverbank of some of the 34 x 7000hL conditioning tanks. The working corridor is underground.

Some of the 14 x 1250hL horizontal bright beer tanks

440mL cans of Skol coming off two can lines

The Krones can filler and Ferrum seamer

A record week on No1 can line

Bottle conveyors with the Sander Hansen pasteuriser on the right

The 1998 Krones bottling line works at 54,000bph

Change parts for the bottling line

The 16 lane APV kegging line dates from 1993 and will fill 1000 50L kegs an hour

Locator board handling is still manual