From Brewery History Society Wiki

Jump to navigation

Jump to search

|

|

| Line 30: |

Line 30: |

| <div>[[Image:P1090860.JPG|thumb|center|400px|A rotating device in the whirlpool to remove the trub cone]]</div> | | <div>[[Image:P1090860.JPG|thumb|center|400px|A rotating device in the whirlpool to remove the trub cone]]</div> |

| </slideshow> | | </slideshow> |

| | |

| <div style="height:1;width:1600px;border:0;border-bottom:3px;border-style: solid;border-color: #000000"> | | <div style="height:1;width:1600px;border:0;border-bottom:3px;border-style: solid;border-color: #000000"> |

| | |

| <gallery> | | <gallery> |

| File:P1090686.JPG|The 1899 brewery buildings will turn into residential properties | | File:P1090686.JPG|The 1899 brewery buildings will turn into residential properties |

Revision as of 18:03, 31 July 2016

<slideshow sequence="forward" transition="fade" refresh="3000">

The 1899 brewery buildings will turn into residential properties

The tops of five 575hL dual purpose vessels moved as part of the new brewhouse project

Three new 150hL FVs were built by Musk, the tops are on the floor below the larger vessels to ensure all the cones are on the same level

View of the vessel cone area

Cones of the three 150hL vessels and a new 375hL FV at the rear

Illustrious forebears of the current family owners

All brewhouse vessel manways are decorated

The grist inlet conveyor and hydrator above the mash mixer

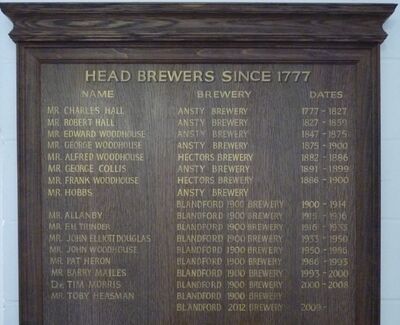

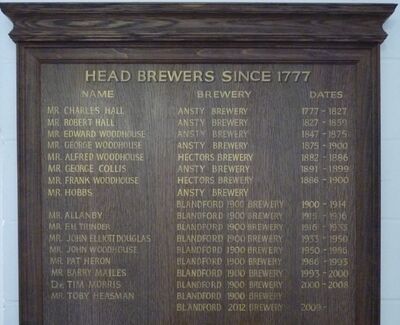

More heritage in the new brewhouse - only 16 Head Brewers since 1777

A timeline for the Company behind the wort prerun vessel and the lauter tun. The nominal brewlength is 150hL at 1050o

The conical topped copper on the left and the whirlpool

Adding the T90 hop pellets

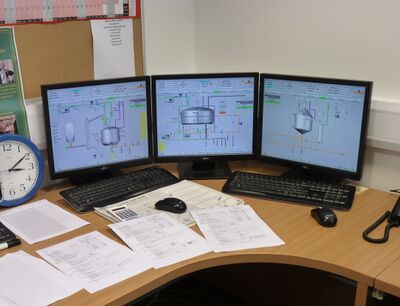

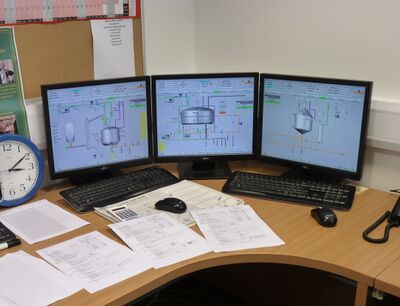

The brewhouse operator's work station using Braumat Compact software

The 300hL raw water tank on the left with acid dosing and the cold liquor tank in the corner

The 1899 brewery buildings are just across the yard

The copper has a tangential wort entry even though the brewhouse has a whirlpool

In the brewhouse basement - trub tank and whirlpool showing the tangential inlet with the external wort boiler behind.

The brewhouse detergent cleaning tanks in the basement

The lauter tun run off tubes

The Seepex displacement pump used to move the spent grains to the silo

Wort cooling heat exchanger and the spent grain main to the silo

Wort oxygenation equipment

The 1899 Boby mill is still in service after new rollers in 1974 and a total refurb

The bulk grain intake station

Another view of the old brewery buildings

The new 40t spent grain silo

Trub tank, whirlpool, CIP set and prerun vessel bottoms

A drawing of the 1899 brewery in the visitor centre. It cost £28,000 which was 40% over budget - perhaps nothing changes!

A rotating device in the whirlpool to remove the trub cone

</slideshow>

The 1899 brewery buildings will turn into residential properties

The tops of five 575hL dual purpose vessels moved as part of the new brewhouse project

Three new 150hL FVs were built by Musk, the tops are on the floor below the larger vessels to ensure all the cones are on the same level

View of the vessel cone area

Cones of the three 150hL vessels and a new 375hL FV at the rear

Illustrious forebears of the current family owners

All brewhouse vessel manways are decorated

The grist inlet conveyor and hydrator above the mash mixer

More heritage in the new brewhouse - only 16 Head Brewers since 1777

A timeline for the Company behind the wort prerun vessel and the lauter tun. The nominal brewlength is 150hL at 1050o

The conical topped copper on the left and the whirlpool

Adding the T90 hop pellets

The brewhouse operator's work station using Braumat Compact software

The 300hL raw water tank on the left with acid dosing and the cold liquor tank in the corner

The 1899 brewery buildings are just across the yard

The copper has a tangential wort entry even though the brewhouse has a whirlpool

In the brewhouse basement - trub tank and whirlpool showing the tangential inlet with the external wort boiler behind.

The brewhouse detergent cleaning tanks in the basement

The lauter tun run off tubes

The Seepex displacement pump used to move the spent grains to the silo

Wort cooling heat exchanger and the spent grain main to the silo

Wort oxygenation equipment

The 1899 Boby mill is still in service after new rollers in 1974 and a total refurb

The bulk grain intake station

Another view of the old brewery buildings

The new 40t spent grain silo

Trub tank, whirlpool, CIP set and prerun vessel bottoms

A drawing of the 1899 brewery in the visitor centre. It cost £28,000 which was 40% over budget - perhaps nothing changes!

A rotating device in the whirlpool to remove the trub cone