Hall & Woodhouse - 12 October 2001: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

<slideshow sequence="forward" transition="fade" refresh="3000"> | |||

<div>[[Image:badger.jpg|thumb|center|400px|Mr Brock presides over the entrance to the visitor facilities]]</div> | |||

<div>[[Image:bottle line.jpg|thumb|center|400px|The new beer bottling line based around a 50 head Ortmann & Herbst filler, 10 head Arol crowner and Krones labeller]]</div> | |||

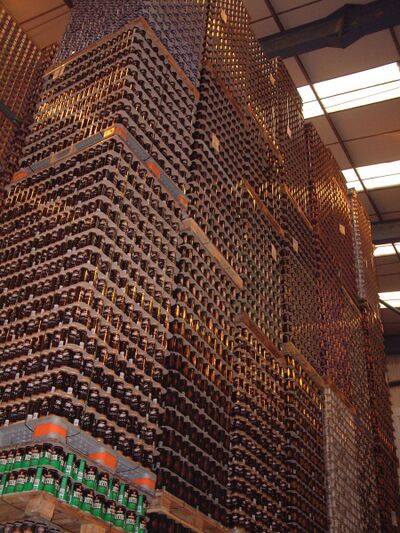

<div>[[Image:can stack.jpg|thumb|center|400px|Maximising the warehouse roof height with empty cans]]</div> | |||

<div>[[Image:cask line.jpg|thumb|center|400px|A four head metered counter pressure cask racker ex Allied at Warrington]]</div> | |||

<div>[[Image:crowner.jpg|thumb|center|400px|The Arol crowner]]</div> | |||

<div>[[Image:david and barrie.jpg|thumb|center|400px|Production Director Barrie Loring (left) with the late David Woodhouse]]</div> | |||

<div>[[Image:drying.jpg|thumb|center|400px|Drying the keg surface before applying export labels - the beer is Bass Pale destined for Japan]]</div> | |||

<div>[[Image:DSCF0018.JPG|thumb|center|400px|The Hall & Woodhouse range]]</div> | |||

<div>[[Image:DSCF0020a.JPG|thumb|center|400px|A old poster for Matthews Wyke Brewery in the visitor centre]]</div> | |||

<div>[[Image:DSCF0022.JPG|thumb|center|400px|A collection of coopers tools in the visitor centre]]</div> | |||

<div>[[Image:DSCF0027a.JPG|thumb|center|400px|The 1899 brewhouse]]</div> | |||

<div>[[Image:DSCF0032b.JPG|thumb|center|400px|The brewery entrance]]</div> | |||

<div>[[Image:DSCF0033.JPG|thumb|center|400px|A stone incised with 1895]]</div> | |||

<div>[[Image:DSCF0099.JPG|thumb|center|400px|30L kegs bound for Japan]]</div> | |||

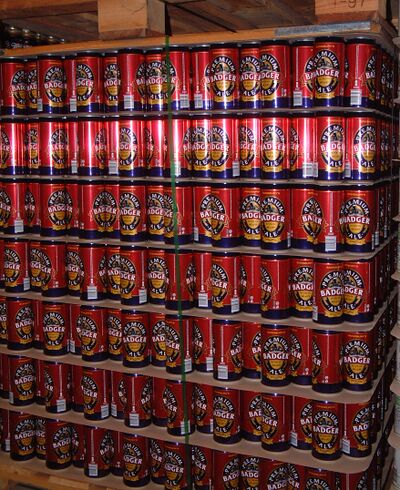

<div>[[Image:DSCF0128.JPG|thumb|center|400px|Empty Badger cans awaiting filling for export]]</div> | |||

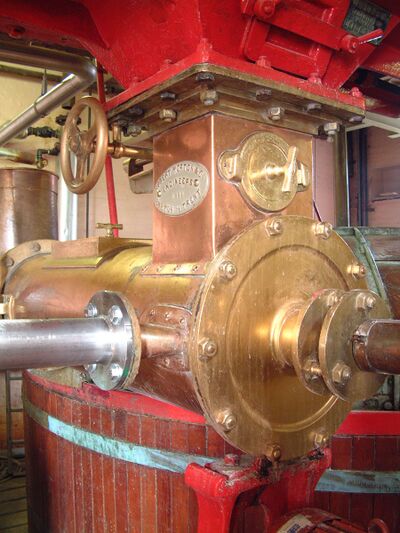

<div>[[Image:DSCF0146.JPG|thumb|center|400px|A Robert Mortons Steels masher]]</div> | |||

<div>[[Image:DSCF0149.JPG|thumb|center|400px|Brewer Jimmy Swann]]</div> | |||

<div>[[Image:DSCF0157.JPG|thumb|center|400px|On the copper hearth]]</div> | |||

<div>[[Image:DSCF0158.JPG|thumb|center|400px|Checking the bulk syrup tanks]]</div> | |||

<div>[[Image:DSCF0159.JPG|thumb|center|400px|Venerable grain conveyor by Nalder and Nalder of Wantage]]</div> | |||

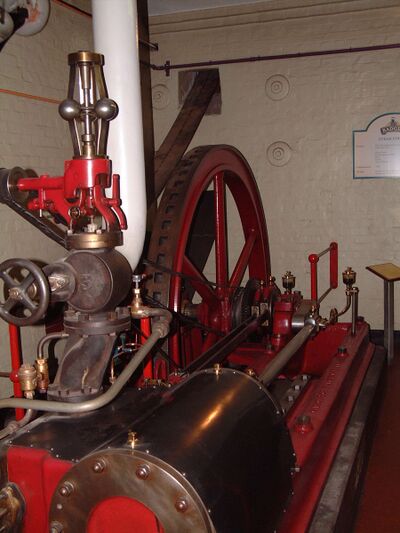

<div>[[Image:DSCF0161.JPG|thumb|center|400px|Venerable steam engine]]</div> | |||

<div>[[Image:DSCF0162.JPG|thumb|center|400px|External dual purpose vessels]]</div> | |||

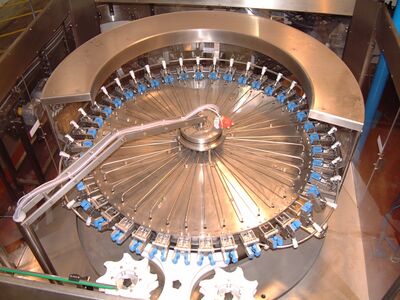

<div>[[Image:filler.jpg|thumb|center|400px|Detail of the 50 head Ortmann & Herbst filler]]</div> | |||

<div>[[Image:FV.jpg|thumb|center|400px|A row of 240brl square fermenters, FV6 and 7 nearest the camera are 120brl split down the middle]]</div> | |||

<div>[[Image:keg pasteuriser.jpg|thumb|center|400px|The BTB keg line pasteuriser - a challenge for the welders]]</div> | |||

<div>[[Image:kegline front.jpg|thumb|center|400px|One of four 50 keg per hour lanes on the BTB kegging machine]]</div> | |||

<div>[[Image:kegline.jpg|thumb|center|400px|Another view of the Cleanomat BTB lanes]]</div> | |||

<div>[[Image:mash tuns.jpg|thumb|center|400px|Two 5t mash tuns dating from 1899]]</div> | |||

<div>[[Image:mimic.jpg|thumb|center|400px|Mimic diagram showing the four kegging lanes]]</div> | |||

<div>[[Image:outside vessels.jpg|thumb|center|400px|External tanks with a view of Blandford Forum in the background]]</div> | |||

<div>[[Image:pasteuriser.jpg|thumb|center|400px|The pasteuriser on the new bottling line - bottles are aseptically filled]]</div> | |||

<div>[[Image:recycling.jpg|thumb|center|400px|The short cut from the town over the bridge and the Recycling Centre dealing with packaging waste from the soft drinks operation on site]]</div> | |||

<div>[[Image:rinser.jpg|thumb|center|400px|The 36 head Cortec bottle rinser]]</div> | |||

<div>[[Image:tim and barrie.jpg|thumb|center|400px|Head Brewer Tim Morris with Production Director Barrie Loring]]</div> | |||

</slideshow> | |||

<div style="height:1;width:1600px;border:0;border-bottom:3px;border-style: solid;border-color: #000000"> | |||

<gallery> | <gallery> | ||

File:badger.jpg|Mr Brock presides over the entrance to the visitor facilities | File:badger.jpg|Mr Brock presides over the entrance to the visitor facilities | ||

Revision as of 17:58, 31 July 2016

<slideshow sequence="forward" transition="fade" refresh="3000">

</slideshow>